Safe Works NSW Fact Sheet

Pallet racking fact sheet

Any racking used in the workplace should be designed specifically for the size, shape and weight of the products being stored.

Background

This advice is for persons conducting a business or undertaking (PCBU), including those with management or control of a workplace and workers. This includes a person in control of racking, warehouse and maintenance, training organisations, forklift operators, store persons and health and safety representatives.

This fact sheet provides guidance for standard pallet racking. Additional safety measures may be required for cantilever, drive-in, double-deep, pallet-live, push-back or other specialised types of racking.

Information has been adapted from WorkSafe Victoria’s guidance note; pallet racking operation and maintenance.

Racking design and layout

Any racking used in the workplace should be designed specifically for the size, shape and weight of the products being stored. It is also important that all racking is set up and maintained according to the manufacturers’ instructions.

The layout of racking should be compatible with the material handling equipment used in the workplace – eg aisle width should match the turning circle of the forklift used for picking and replenishment.

The layout should also consider emergency access, adequate lighting and any manual handling activities.

Rated capacity

There are two critical rated capacities related to racking and they should never be exceeded. They are:

- maximum unit load

- total rated capacity for each bay

Unit load is an individual stored item – eg a pallet having material that can be placed or retrieved in one operation.

Total weight of unit loads stored on a bay must not exceed the rated capacity of the bay.

This information should be provided to people who use the racks. One of the most effective means of providing this information is to mark it clearly in a visible location on the racking.

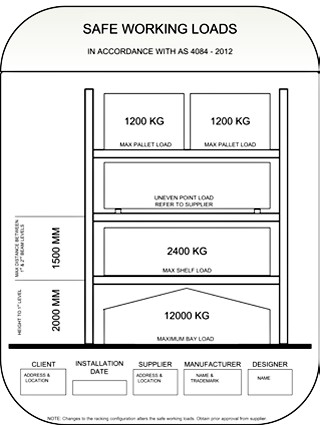

The racking supplier should provide the following:

- racking manufacturer’s name, supplier’s name and trademark, and the installation date

- designer’s name (company or individual)

- working unit load limit

- total working unit load limit for each pallet beam level

- total working unit load limit for each bay

- maximum distance from the base plate level to the first beam level and maximum distance between adjacent beam levels

There should always be some way of determining the weight of each unit load being placed into the racking. See figure 1 for an example of safe working loads

Modifications to racking design or components

Modifications should only be made by a competent person who has been given all the information provided by the supplier.

Any modifications to the racking should take into account the effect on load limits and should also be approved by the manufacturer, supplier or a qualified engineer who has knowledge and experience in similar work. Operating procedures, signs and drawings must be updated to include details of the modification.

Never make physical alterations to uprights, bracings, beams or components – eg welding on additional cleats or bearers without the approval of a competent person.

Replacement of uprights, bracings, beams, clips or other components should be done using parts from the equipment manufacturer. If alternative parts must be used, an engineering report should confirm that they are compatible with racking being repaired.

Single bay racking

In situations where pedestrians can access the back of the racking, and single rows have been installed, rear protection should be fitted to prevent loads falling out of the back of the racking.

Operating instructions

Put procedures in place to ensure operations are done safely with regard to the racking design, the load and capability of lifting equipment (see figure 2).

As a minimum, these should include:

- correct use of the handling equipment

- rated capacities of the racking

- prohibitions on unauthorised alterations

- a clear process for reporting any damage as soon as it occurs

Selection of pallets and goods on pallets

Pallet racking should take into account the nature of goods in the unit load. An assessment of any change to the pallet design should be done by a competent person to prevent problems – eg:

- changing from timber pallets to post pallets will apply concentrated loads on racking beams and the pallets may not key into the beams

- using pallets larger than in racking design can overlap pallets behind or push them off their supports

- using pallets smaller than allowed for, in the racking, can make them drop through

- using skid pallets in racking without timber decks can allow them to drop through

Potential problems that may require changes to racking design include:

- boxes, cartons and other items overhanging the pallet they are stored on (unless the racking structure has the correct clearance)

- falling items from boxes, cartons and other loose loads stored on upper levels (unless this is prevented by wrapping, strapping or by some other means – eg end frame extensions and pallet safety backstop)

Note: Overseas pallets often differ in size and may not fit Australian racking.

Collision protection – mobile plant

The work health and safety legislation requires the person with control or management of mobile plant to manage the health and safety risks of plant colliding with people, other mobile plant or stationary items. A traffic and pedestrian plan should be developed.

Bottom portions of frames exposed to possible collisions by forklifts or other moving equipment should be fitted with upright protectors and end-of-rack protectors.

Reporting unsafe situations and damage

All safety risks related to operation or maintenance of the racking should be reported to management immediately. In some circumstances – eg major collapse of racking exposing a worker or others to serious health and safety risks, SafeWork must be notified immediately by calling 13 10 50.

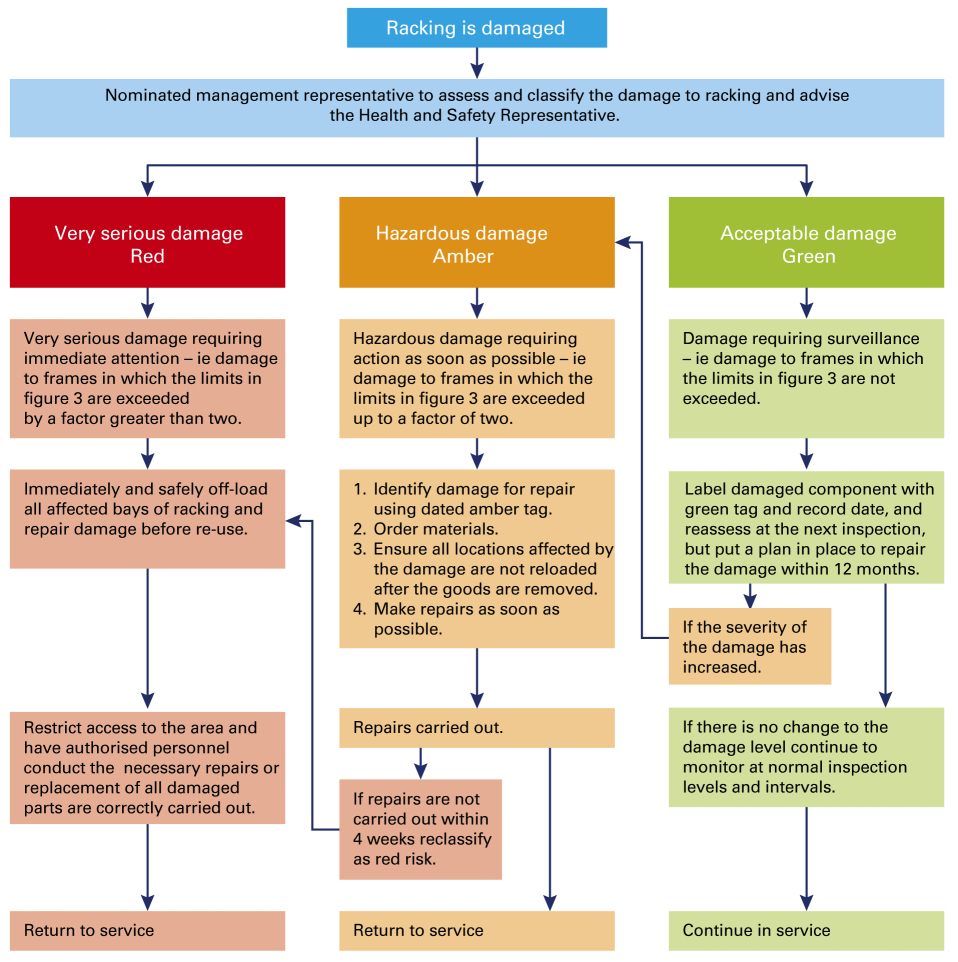

Workers should report any damage to a supervisor immediately so it can be inspected and assessed. Damage should be recorded – eg coloured stick-on tags used to show the location and level of damage. See figure 3.

Inspections

The work health and safety legislation requires that plant and structures (including racking) are without risks to health and safety. To ensure this, racking should be inspected regularly to confirm its integrity. For guidance on inspections, refer to AS 4084: Steel storage racking.

When doing inspections, consider the following questions:

Beams

Are beams overloaded?

Deflection indicates overloading of the racking. Where two beams connect at an upright, the beam connectors should be parallel.

If racking is or has been overloaded, the beam connectors may be deformed (forming a ‘V’).

The amount of permanent deformation should not exceed the maximum allowed by the manufacturer. In this situation, the racking should be inspected by a competent person.

Are beams or welds damaged?

Check for obvious signs of beams being hit by a pallet or forklift. Damaged beams should be replaced. If a beam has been hit and is only showing minor damage, ensure welds are checked for cracks by a competent person.

Are beam connectors or safety clips missing?

Examine beams for damage and replace missing clips. The design of the replacements must be approved by the racking manufacturer. If clips are regularly being dislodged, contact the manufacturer or installer to determine why, and take the necessary action to fix it.

Has a beam popped out of its upright?

If a beam has popped out this will mean it is only suspended on one end connector and could collapse.

Are the anchor bolts that secure the racking to the ground loose?

Inspect anchor bolts regularly to ensure they are appropriately tightened. Adjust as required.

Rated capacity

Are rack load signs legible?

To ensure load signs are legible check that:

- markings/signs displaying the rated capacities can be seen by workers

- rack configurations have not been altered

Uprights and footplates

Are uprights damaged?

If an upright shows damage (see figure 4), is twisted or contains splits or cracks, replace it or splice in a new section. Splices should be approved by the racking manufacturer. Replace any damaged uprights and footplates.

Are splices in good condition?

Check the condition of all splices. They should be above the first beam level, not below 1.5m, and no more than one splice should be between any two adjacent beam levels.

Out of plumb

Is the racking vertical?

Out of plumb racking is usually caused by incorrect installation but can also be the result of impact, overloading, or settling of the floor slab. Contact the manufacturer or installer.

Braces

Are racking braces damaged?

Replace bent, horizontal or diagonal braces. For bracing, the member deviation from a 1m long straight edge in either plane should not exceed 10mm.

Floor fixings

Are floor fixings installed?

Check floor fixings are installed and undamaged. If damaged, replace it and the footplate. At least two anchors are required in each footplate.

Further information

Review the following Australian standards:

- AS4068: 1993 Flat pallets for materials handling

- AS4084: 2012 Steel storage racking

- AS4762: 2000 General purpose flat pallets, principal dimensions and tolerances